Oil extraction plants deal with removal of oil from the seeds of a plant. The oil is usually used in cooking, beauty and aromatherapy. There are several methods that are used to extract these oils. These methods vary in terms of cost and you will need to consider your budget when choosing one.

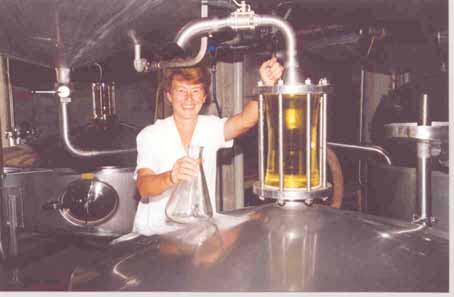

There are some factors to consider when starting oil extraction plant. The scale of production should be the first thing. If you are planning to produce oil in large scale, you will need a big machine that can handle high quantities production. Distillation is the primary method of oil extraction. This method involves putting the seeds or plants in boiling water or under steam and leaving the fats to breakdown into vapors. Make sure to clean the seeds and dry them before heating them.

You can also crush the seeds to make the extraction faster. After heating, the vapor will cool down in a tank with the oils on the top while the water will go to the bottom of the tank. You can collect the oil and put it in cans for future use. The main sources of these oils include corn and soybean which is the most widely used oils in the world. Sunflowers, rapeseed, cotton, coconut, olive and palm oil are also gaining popularity with some being used in the production of bio-fuel.

To extract oil from plants, all you need are the right equipments and techniques. Some farmers are taking advantage of their plants to produce oil at home instead of buying from manufacturers. The method of extraction might vary depending on the seeds you are using, but with a pestle, expeller and cold press you can produce oil at home. Oil extraction plants involve the removal of essential oils from plants. Make sure you have the right equipment and techniques for this process.